Sulfur Recovery and Acid Making Technology

Ningbo FareastTech Catalyst Engineering Co.,Ltd was established in 2008, it is a national high-tech enterprises who is engaged in chemical technology package, engineering technological transformation and new materials development and promotion.It is organized by the management and technical team of the former Ningbo Chemical Industry Institute. It has been committed to providing technical services such as desulphurization, salt extraction, acid making and flue gas removal for the vast number of enterprises.

As the country puts forward new environmental emission requirements for the coking industry, the demand for H2S gas treatment technology in low quality sulfur paste, desulphurization waste liquid and coke oven gas is further improved by the coking enterprises.In view of the existing technology, the organizational forces of the central Fareast Tech are developed and tested. After years of tackling and combining with traditional technology, "ISS Wet Oxidation Desulfurization Technology", "Sulphur Paste and Desulphurization Waste Liquid Acid Making Technology" and "Desulphurization Waste Liquid Salt Extraction Technology" have been developed.

The success of technology is inseparable from good research platform.Over the years, Fareast Tech has set up an engineering center with the Ningbo Materials Institute of the central and Chinese Academy of Sciences, and has established close technical cooperation with the Zhejiang University and the South American environmental protection company.Technical team give full play to its own skills and provide new solutions and technical ideas for low quality dust sulphur paste, desulphurization waste liquid, desulphurization mixed salt and waste gas treatment in the coking industry.

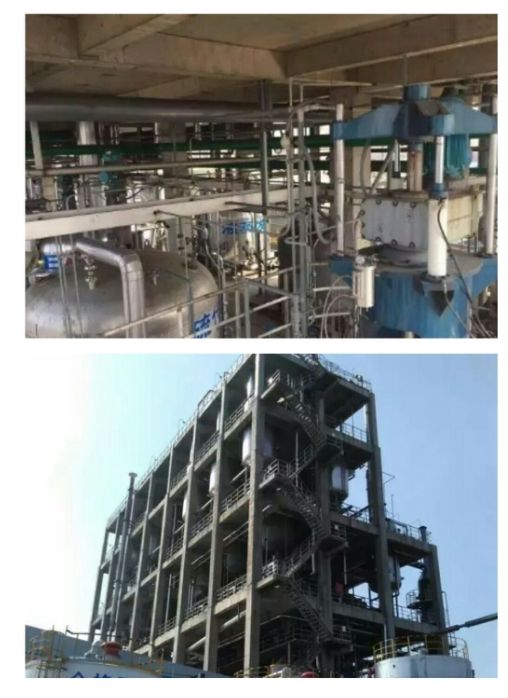

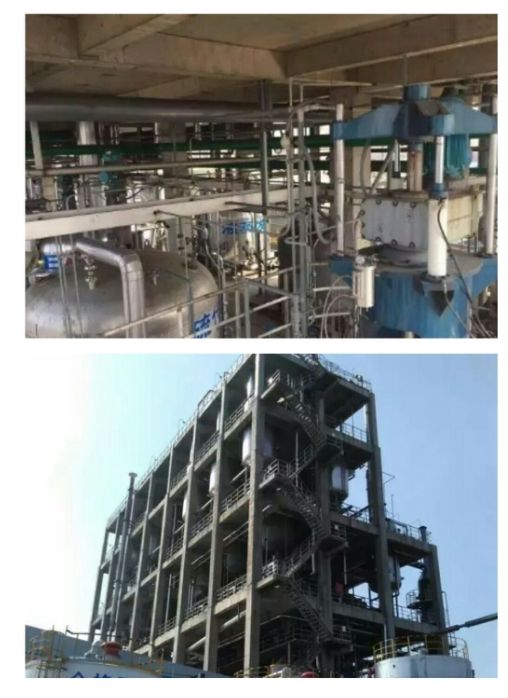

Operating device

A.Operation picture of "ISS Wet Oxidation Desulphurization" device

B.Operation of "Sulphuric Acid Ointment and Desulfurization Waste Acid" project installation

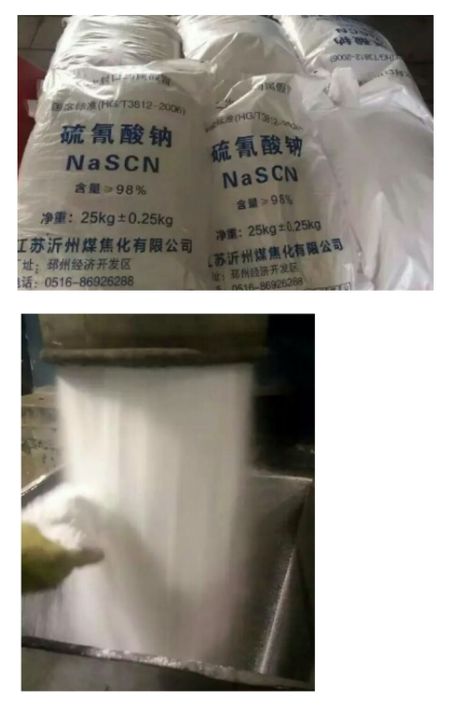

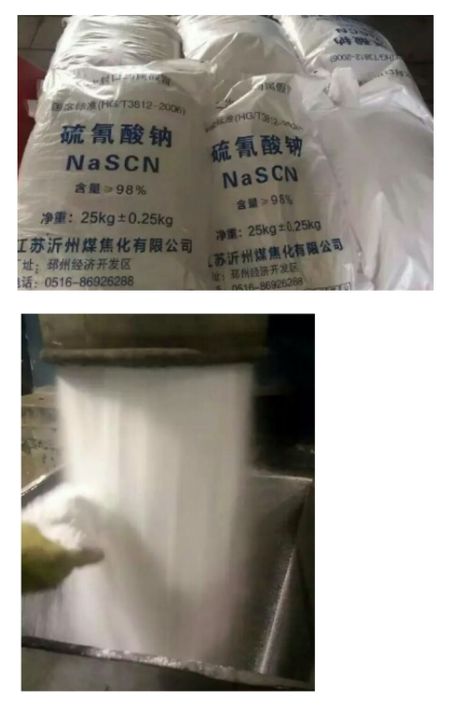

C.Operation picture of the project "Removing Salt from Waste Liquid of Desulphurization"

1. ISS Wet Oxidation Desulfurization Technology

(1).It has high desulfurization efficiency, H2S removal rate is greater than or equal to 99%, organic sulfur (COS, CS2 and RSH) removal rate is more than 55%, HCN removal rate is 100%;

(2). In the process of operation, the sulphur quality is high and the sulfur is not blocked by the tower. The sulfur of the pipes and fillers can be removed when the equipment is running normally. It has a good cleaning tower ability;

(3). ISS desulfurizer has good selectivity and low secondary salt generation rate, which can effectively reduce alkali consumption and reduce production cost;

(4). This series of desulfurizer has low consumption, low consumption and economic operation;

(5). The ISS desulfurizer has good activity and strong regeneration ability. The sulfur produced by the product is easy to floatation, large particles, easy to melt sulfur, low sulfur consumption and low sulfur recovery efficiency;

(6). ISS desulphurizer is simple, simple in operation and simple in management.

B.Sulfuric Acid Technology of Sulfur Paste and Desulphurization Waste Liquid

(1). There is no waste residue and exhaust gas in the process, and some waste liquid is produced to remove the existing sewage treatment;

(2). According to the actual situation and actual production capacity of each enterprise, considering the size of the feeding, the operating cost and the difficulty of operation, the feed or dry powder feed of the boiling furnace with slurry feed is adopted to ensure the stability of the feed and the full combustion and decomposition of the material;

(3). The waste heat boiler uses special structure to avoid the problem of impurities and dust blockage. At the same time, it uses relevant means to clean up in time, so as to achieve the requirement of cleaning up boiler ashes without stopping production;

(4). The tail gas is provided with an ammonia water absorption unit, and the exhaust gas is discharged through an electric mist eliminator,SO2≤50mg/Nm3;

(5). The localization rate of process equipment and materials is more than 90% by adopting domestic technology and equipment;

(6). As a environmental protection device, the sulfur ointment and salt containing waste liquid produced by the wet oxidizing ammonia gas desulfurization unit, or sulfur containing flammable substances such as sulfur paste and sulphur, are used to produce high quality sulfuric acid and secondary medium pressure steam, energy saving and consumption reduction, and the waste utilization has been achieved, which brings good economic benefit.

C.Technology for Extracting Salt from Waste Liquid of Desulphurization

(1). The process has the characteristics of good selectivity, high purity, energy saving and environmental protection. The purity of sodium thiocyanate extracted by soda method can reach more than 99.5%.The purity of sodium thiosulfate is more than 98%. The ammonium content in ammonium sulfate extracted by ammonia is more than 20.5%, ammonium sulphate is more than 96%, and ammonium thiocyanate content is less than 0.5%;

(2). The device makes full use of desulphurizing waste liquid in desulphurization section. The process is simple and feasible, saving energy, no emission of "three wastes", and is conducive to environmental protection;

(3). The process of solvent recovery and utilization, cooling water form closed cycle, low production cost, good economic and environmental benefits;

(4). The device uses advanced DCS distributed control system to monitor the process parameters of the whole process. The whole production process monitoring can be completed in the main control room, and the labor cost is low.